Wiping Systems

Efficient Wire Production

Energy Awareness

We offer a wide range of stripping systems for commercial and heavy coating. In particular, the automatic control of zinc application ensures uniform coating thicknesses and minimal zinc consumption.

Mechanical Systems

We offer mechanical systems with durable wiper pads for vertical or inclined pull-out, mainly for normal galvanizing with 30 to 130 g/m². They are easy to maintain because the pads can be replaced within one to two minutes.

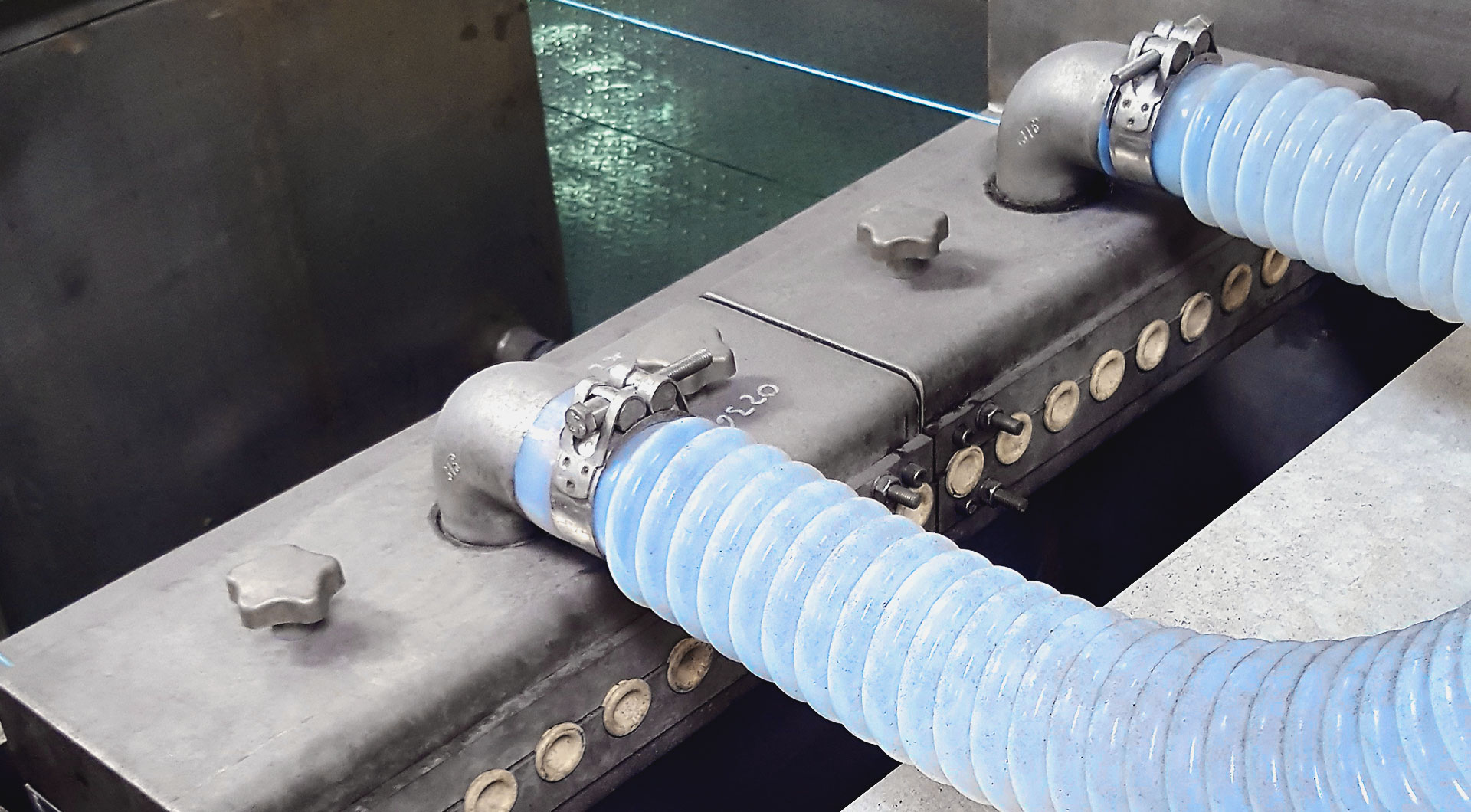

Nitrogen Wiping

Nitrogen wiper systems are used for Class A, B and C overlays at high DxV. They are suitable for:

- Wire diameter between 0.8 and 9.0 mm

- Zinc coatings between 85 and 600 g/m²

- Pitch minimum 35 mm

With manual adjustment options in several axes, the scraper nozzles can be precisely adjusted and calibrated. This ensures that the wire runs concentrically through the nozzle and that a uniform thickness of the zinc coating is achieved over its entire circumference. The individual wire guidance makes it possible to coat wires with different diameters and correspondingly different speeds simultaneously in the same system. Compared to conventional systems, up to 300 percent higher line speeds can be achieved, resulting in a significant increase in the productivity of the entire line by up to ten percent.

The nozzles are made of hardened stainless steel and therefore require

little maintenance.

Product sheet Wiping Systems

Download (PDF)